- Polymers are chemicals with extremely high molecular weights.

- They are divided into natural and synthetic, as well as modified.

- Polymers are produced by polymerisation or polycondensation.

- They can then be used with various modifiers to produce plastics.

- It is found in the production of packaging, medicine, construction, electronics and many other industries.

Polymers, both natural and synthetic, are an integral part of the modern world, finding applications in virtually every aspect of our lives and in many areas of industry. They are materials with unique properties specific to each group, making them extremely versatile and used in many different industries. In this article, we will look at the diversity of polymers, their properties and applications.

What are polymers and what properties do they have?

Polymers are chemicals that have a very high molecular weight. They are made up of many fragments that are repeated many times – these are called meres. The disconnection of one mer or the connection of another should not change the properties of the compound significantly (e.g. melting

Each polymer may have characteristic properties that determine its use. Common characteristics of all polymers are:

- high strength and low weight;

- resistance to chemicals;

- they are good insulators, both in terms of electrical and thermal energy;

- high ductility, which allows for easy processing and the creation of various structures and materials.

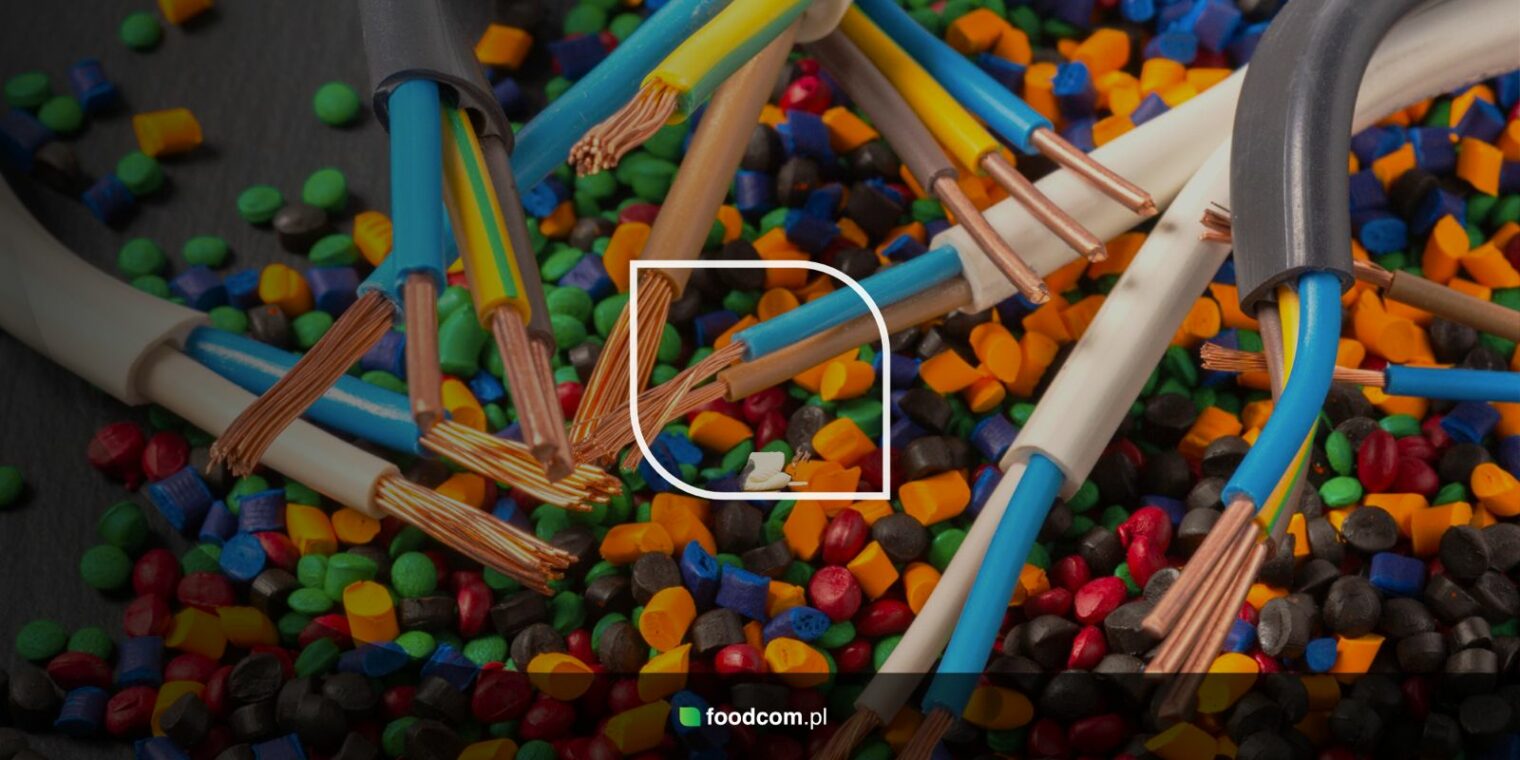

All these properties make polymers applicable as various types of plastics used in different areas of industry.

Division of polymers

The basic division of polymers is based on their origin. A distinction is made between natural polymers, synthetic polymers and natural polymers that have been artificially modified. We can also divide polymers according to:

- topology (the chemical composition, architecture and configuration of the molecule and the ways in which the individual mers join together) – we distinguish, for example, linear, branched, ladder, cyclic and cross-linked polymers;

- by homogeneity of chemical structure – polymers can be composed of the same mers (homopolymers) or of several mers of different structure (copolymers);

- by structure, e.g. crystalline and amorphous polymers;

- by structure – the basic division includes organic and inorganic polymers, depending on whether or not carbon atoms are present in their main chain. With regard to the type of bonds and molecules present in the polymer, we distinguish between such organic polymers as polyolefins, vinyl polymers, polyethers, polyamides, polyurethanes, polyesters, polycarbonates and polypeptides.

Natural polymers

Natural polymers, otherwise known as biopolymers, are produced 100% by living organisms as their building blocks. These include substances such as:

- polysaccharides: cellulose, starch, glycogen,

- proteins, including enzymes,

- nucleic acids,

- lignin,

- natural rubber,

- alginic acid,

- collagen,

- gelatine.

Biopolymers can be used, for example, in the production of various materials (rubber, paper), in biomedical engineering (e.g. tissue engineering), the food industry, enzyme production and many other industries.

Synthetic polymers

Synthetic polymers are derived 100% from chemical synthesis processes. The monomers for their production are obtained directly from petroleum or from other syntheses: synthesis gas-based, organic, inorganic and organometallic syntheses. Examples of synthetic polymers are:

- Teflon (also known as PTFE – polytetrafluoroethylene or tarflen),

- polyethylene (PE),

- polypropylene (PP),

- polystyrene (PS),

- polyacrylonitrile (PAN, anilanthene),

- polyethylene terephthalate (PET),

- polyvinyl chloride (PVC, PVC),

- polyethylene oxide (PEO, “artificial steel”),

- nylon,

- synthetic rubber,

- polylactide (PLA),

- polysiloxane,

- polymethylmethacrylate (PMM, organic glass),

- phenoplastics,

- epoxy resins,

- polyamide,

- polycarbonate,

- polyurethane.

Modified polymers

Modified polymers are natural polymers that have been artificially modified chemically. The modification usually aims to change the functional properties of the polymer. Examples of modified polymers are:

- cellulose acetate,

- modified protein,

- modified starch

Production of polymers

Synthetic polymers are produced through chemical synthesis processes. They are usually obtained by performing a polymerisation reaction on monomers, i.e. molecules of the same or different chemical compounds that are capable of forming polymers. An initiator is required to start the reaction, and the rate of the process is controlled by the presence of a catalyst, as well as the prevailing pressure and temperature. Polymerisation can occur gradually or in a chain (avalanche). Technically, polymerisation can occur in a variety of media: in solution, micelles, suspension, gas phase, at the interface, in a block formed by the direct addition of an initiator to a liquid monomer. Polymerisation can also be radiation-initiated – initiated by ionising radiation. Polymers such as polyethylene, polyvinyl chloride, polypropylene and polystyrene can be obtained by polymerisation.

The second way of producing polymers is by polycondensation, during which another substance, such as water, ammonia or hydrogen chloride, is produced in addition to the polymer. This is a stepwise process. Polyamides, phenol-aldehyde and epoxy resins, as well as some polyesters are produced in this way.

The polymers obtained by polymerisation or polycondensation are then used to produce plastics. This process requires the use of various types of stabilisers, modifiers, plasticisers or fillers to produce materials with the desired properties. A well-known manufacturer of such additives is Foodcom S.A., whose product range includes, for example, zinc oxide, which is used as a stabiliser in rubber production, glycerine, which is used as a plasticiser, or isopropyl acetate, which is a solvent used in plastics production.

Applications of polymers

Polymers can have different properties that determine their use. Most commonly, polymers are found in the form of various types of plastics. They can be used in areas such as:

- medicine (e.g. tissue engineering, disposable devices, implants, 3D printing),

- packaging (e.g. films, plastic bottles, containers, milk cartons, commercials),

- construction (e.g. thermal insulation materials, films, sealing materials, damp proofing, cladding and lining, panels, e.g. polycarbonate, window profiles, gutters and pipes, paints, lubricants and varnishes, adhesives, joinery materials),

- electronics (e.g. wiring manufacture),

- transport (for the manufacture of machine parts, gears, car upholstery, glass, anti-corrosive paints, adhesives),

- cosmetics (e.g. polyethylene used in the manufacture of nail polish remover),

- household (e.g. containers, toys, transparent glass),

- textiles and upholstery (e.g. production of artificial fibres, e.g. nylon, rope, artificial silk, Gore-Tex fabric),

- sport (production of ropes and lines used in climbing, fishing, sailing, production of skis and sails).

Polymers – the market in Poland

Polymers have been traded in Poland for many years by a number of compounders, such as Grupa Azoty, Synthos, Anwil, Lerg, Ciech Sarzyna, BOPS. Grupa Azoty is a leading chemical manufacturing representative in Poland, offering a wide range of polymers, including polyamides, polypropylenes and speciality composites. Synthos specialises in rubber, styrene and polystyrene, while Anwil specialises in PVC. Lerg and Ciech Sarzyna mainly produce resins.