- IQF is a modern method of freezing products, including fruit, which allows them to retain their natural appearance, taste and nutritional value.

- In the IQF process, each piece of fruit is frozen separately, so it does not stick to other pieces, maintaining its appearance and functionality.

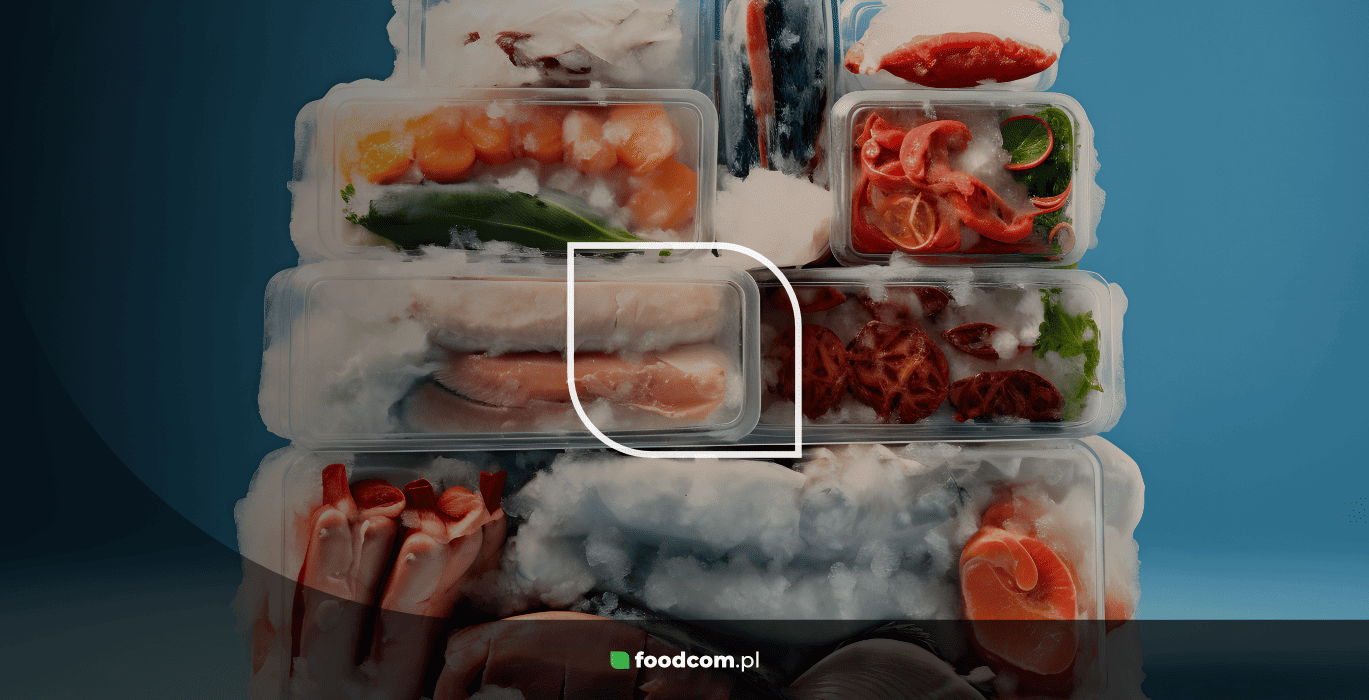

- This technology is ideal for freezing fruits such as strawberries, raspberries, currants, blueberries and gooseberries, as well as mixtures of vegetables, meat and fish.

What is IQF freezing and what does it involve?

IQF, or Individual Quick Freezing, is a method of fast, individual freezing that preserves the maximum quality of fruit, vegetables, meat or fish. This technology is particularly appreciated in the case of fruit, because – unlike traditional freezing methods, where products clump together and lose their structure – IQF ensures that each fruit is frozen separately and retains its natural shape.

The IQF process takes place at very low temperatures – usually between -30°C and -40°C, although temperatures can be much lower – using an intense stream of cold air in special freezing tunnels. This results in immediate shock freezing, during which no ice crystals are formed, as is the case with traditional product freezing. Such crystals can penetrate the cell structure, altering the consistency of the frozen products and being the cause of water and nutrient loss on thawing, which is not the case with IQF.

What are the advantages of IQF frozen products?

IQF freezing instantly stops enzymatic and bacterial activity and freezes immediately, which translates into:

- long product shelf life without the need for preservatives;

- no loss of nutritional value or product consistency;

- time saving (faster freezing, no need to defrost the product before heat treatment);

- increased safety, especially for meat and fish;

- ecology (paper instead of plastic packaging can be used for freezing).

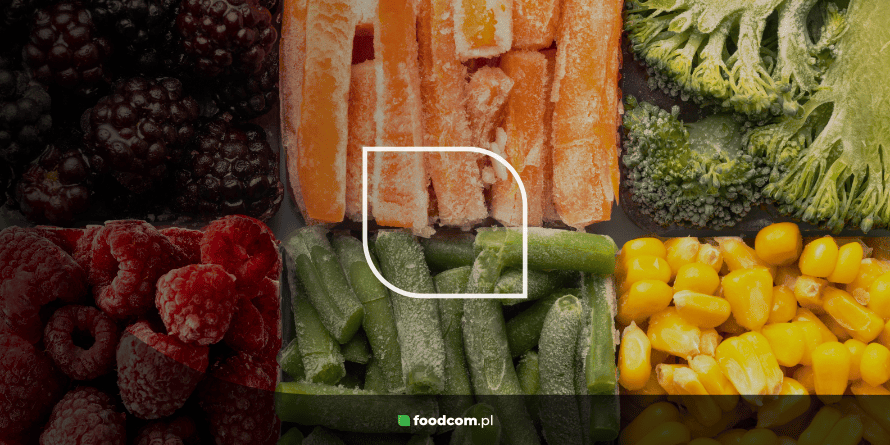

In the case of IQF frozen fruit, the advantage of this method is mainly the preservation of the colour, shape and appearance of the fruit, which is aesthetically pleasing and easy to measure accurately. The product also does not lose valuable vitamins and trace elements. IQF fruits are ideal for direct use as well as for cooking, baking or blending. They are also used by producers of juices, jams or desserts, as this technology allows the use of seasonal fruit all year round, without sacrificing high quality.

Which fruits are frozen using the IQF method?

Companies such as frozen food wholesaler Foodcom S.A. – an experienced supplier of food products – offer a wide range of IQF frozen fruit available all year round. Among the most popular fruits are:

- strawberries – frozen whole, halved or diced; retaining their natural aroma and sweetness; ideal both for direct consumption and for cakes, cocktails, desserts, jams;

- raspberries – very delicate, thanks to IQF, perfectly protected against bruising; ideal for baked goods, jams or sauces, and as a garnish for desserts;

- blueberries – thanks to IQF freezing, they do not spill or stick together; they can be measured out in small portions, making them ideal as an addition to quick smoothies, baked goods, ice cream and muesli;

- blackcurrant and redcurrant – during IQF freezing, the fruits retain their shape, colour and intense aroma, as well as their high vitamin C content; they are great for preserves, mousses, jellies, juices, as well as an addition to teas and yoghurts and as a garnish for desserts;

- gooseberries – this is a less popular fruit, but increasingly popular for making jams, jellies or premium preserves.

Why is IQF the future of frozen food?

IQF freezing is a technology that allows products to be stored in an almost unchanged form – nothing like their fresh form, ready to use at any time. This is a major step forward compared to traditional freezing, which often compromises product quality.

Among other things, IQF gives consumers and producers the freedom to use seasonal fruit – whatever the season, the availability and quality of each fruit remains high. Fruits frozen by IQF also allow for reduced food losses and increased efficiency in product processing and packaging.

The demand for high-quality frozen products, particularly fruit, is growing year on year – consumers value the convenience, lack of seasonality and high nutritional value of frozen products. IQF technology not only meets the needs of the market, but also shapes its future.