- Cocoa goes through a multi-stage processing process – from fermentation and roasting to grinding and pressing.

- Key steps such as conching and tempering influence the taste, texture and quality of the chocolate.

- Cocoa butter, cocoa powder and cocoa mass are widely used in the food and cosmetics industries.

- The quality of the final products depends on the growing conditions, processing methods and care taken during the production process.

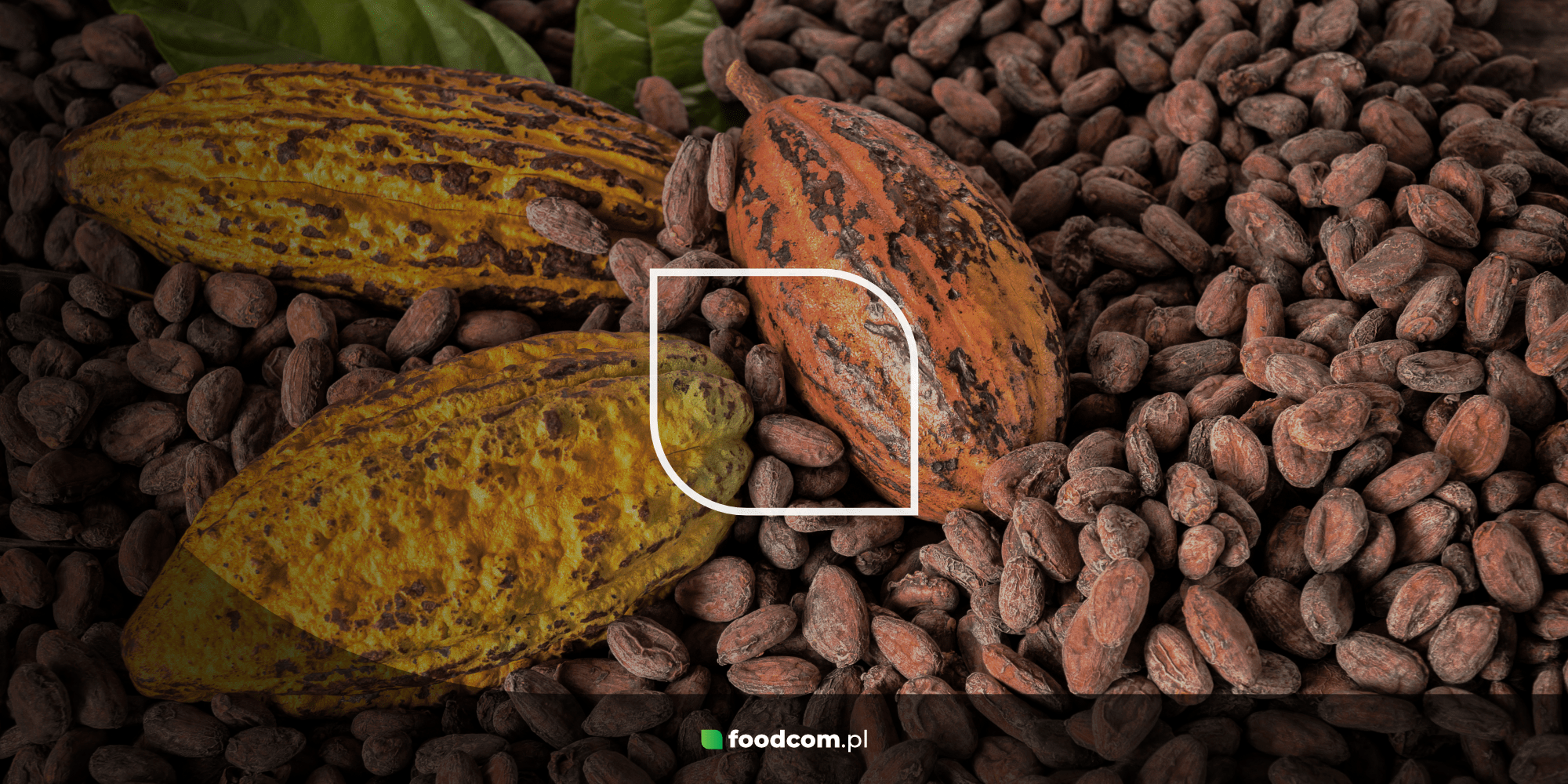

Cocoa is a raw material without which it is difficult to imagine the food and cosmetics industry. It is what is used to make chocolate, cocoa powder or cocoa butter, but it has to go through a long processing process before it reaches the final products.

From fermentation and roasting to grinding and pressing to tempering, each stage influences the taste, texture and quality of the final product. Precision and the right processing methods make the cocoa beans into a product that is valued around the world.

First stage: roasting and cleaning

After harvesting, the cocoa fruits are opened and the seeds are fermented, which lasts from a few days to a week. This process is important for the development of flavour – it is during this time that the chemical reactions take place that give the beans their characteristic aromatic profile. After fermentation, the seeds are dried and then transported to processing plants, where processing begins.

The first step is roasting, which is the heating of the grains at a controlled temperature. This process brings out the deep aroma, reduces acidity and gives the cocoa the right flavour profile. Each manufacturer adjusts the roasting time and temperature depending on the species of cocoa and the effect they want to achieve in the final product.

After roasting, the beans go through a cleaning process known as winnowing. During this process, the hard shells are mechanically separated from the edible part, the roasted cocoa nibs. It is these that form the basis for further processing.

Grinding and cocoa mass formation

The roasted cocoa nibs go to mills where they are ground at high temperatures. Friction releases the natural fat, or cocoa butter, so that the cocoa begins to take on a liquid form. The result is a thick, dark brown cocoa mass, which is the basis for chocolate and cocoa powder.

At this stage, the production process branches out in several directions. The cocoa mass can be used to make chocolate or further processed to produce a variety of cocoa products. The processing of cocoa mass requires care and precision, as the way it is further used affects the properties of the finished product.

Pressing: cocoa butter and cocoa powder

If the cocoa mass is to undergo further separation, it goes into hydraulic presses that squeeze the fat out of it. Under high pressure, the two main components – cocoa butter and the so-called cocoa cake – are separated.

Cocoa butter is the basic ingredient in chocolate, influencing its texture and consistency. The higher its content, the creamier and softer the chocolate. Conversely, a lower amount of fat makes the final product harder and crisper. In addition to the food industry, cocoa butter is widely used in cosmetics and pharmaceuticals – its moisturising and regenerating properties make it a popular ingredient in lotions and creams.

The cocoa cake that remains after pressing is a hard, dry paste that is then crushed and ground into a fine powder. This produces cocoa powder – a raw material used in the preparation of drinks, desserts and baked goods.

Chocolate production – conching and tempering

In order to make chocolate from cocoa mass, it has to be processed properly. It is first mixed with sugar, milk (in the case of milk chocolate) and other ingredients such as vanilla or emulsifiers. It then goes through the conching process – prolonged stirring at a high temperature.

Conching is one of the most important stages in chocolate production. It makes the structure of the chocolate smoother and the taste more balanced. This process can last from a few hours to even a few days – the longer it takes, the smoother the texture and more refined the taste of the chocolate.

After conching, the chocolate must be tempered, which is a controlled cooling and reheating. This stage allows for stable fat crystals, which affects the texture, shine and shelf life of the chocolate. Well tempered chocolate has a perfectly smooth surface, cracks pleasantly when broken and does not melt too quickly in the hands.

Finishing the product and using cocoa

Once all the technological processes have been completed, the chocolate can be formed into bars, pralines or other shapes. It is cooled, packaged and transported to distributors around the world. Cocoa powder, cocoa butter and cocoa mass also find their uses in the food and cosmetics industry.

Cocoa powder is widely used in the preparation of beverages, cakes, ice cream and desserts. Cocoa butter goes into moisturising cosmetics and is also used in pharmaceutical production. In addition to chocolate production, cocoa mass is also used in confectionery and as an ingredient in high-quality creams and fillings.

Cocoa quality and its influence on the final product

Not all cocoa is the same. Its quality depends on the growing conditions, fermentation method, roasting and further processing. The best chocolates and cocoa products are made from beans sourced from quality-controlled cultivation, where every stage of processing is closely monitored.

Artisan chocolates, produced in smaller manufactures, often have a more intense and complex flavour because the conching and tempering processes are longer and the ingredients themselves of higher quality. Large corporations often use shorter processing methods, which affects the flavour profile and texture of the final product.

Cocoa production is a multi-step process that requires precision and knowledge of technology. Each stage – from bean fermentation, roasting, grinding and pressing to conching and tempering – affects the final product. A variety of products, from chocolate to cosmetics and pharmaceuticals, can be obtained from a single raw material.

Through proper processing, cocoa retains its flavour characteristics, ensuring that the finished product meets the highest quality standards.

![Storm on the plant-based market – latest disruptions and outlook [74th Edition of the PLANT-BASED Newsletter] Storm on the plant-based market – latest disruptions and outlook [74th Edition of the PLANT-BASED Newsletter]](https://foodcom.pl/wp-content/uploads/2023/08/Foodcom_SA_Newsletter_Plant-Based-600x300.jpg)

![Short bounce or longer market cooling? An update from the dairy sector [288th Edition Foodcom DAIRY Newsletter] Short bounce or longer market cooling? An update from the dairy sector [288th Edition Foodcom DAIRY Newsletter]](https://foodcom.pl/wp-content/uploads/2023/08/Foodcom_Newsletter_Dairy-600x300.jpg)